A Spanish manufacturer of high-quality equipment for gastronomy and hotel industry, trade and the food industry. The company has specialized in the production of dynamic food preparation equipment since 1961.

The devices we have selected for our offer meet even the most demanding expectations of chefs.

- SmartVide submersible circulators

- cutters, emulsifiers and cutters, and multifunctional devices

- hand mixers, planetary and turbo mixers with high performance

- meat grinder

- potato processing equipment

- juicer, salad centrifuge

- vacuum packing machines

SmartVide submersible circulators.

With the sous-vide method, we can prepare all products from vegetables and fruit, through meat, fish and seafood, to any other products where the chef’s imagination is the only limit. It is worth cooking sous-vide because, apart from the exceptional taste, this method brings many additional benefits.

Better control of the cooking process

In the Grafen offer we present circulators of the renowned Spanish producer Sammic, which are additionally equipped with, among others a Bluetooth connection that allows for more effective HACCP control of the cooking process, saving your own parameters or viewing the temperature and working time.

Uniqueness and unlimited possibilities

The circulator allows you to create new, surprising flavor combinations. The only limitation is the fantasy of the chef.

Precise temperature control system with an accuracy of 0.01 ° C

Top-class precision, extremely important, among others when cooking delicate products such as fish, vegetables or fruit.

Choppers

Extremely efficient (some models even up to 1000 kg / h) and strong. For smaller applications (points) in the Compact version

- with variable speed

- with constant speed

Durability

professional Sammic cutters designed with ergonomics and business continuity in mind. Made of stainless steel.

Comfort of work

Extremely quiet devices have a positive effect on working conditions and are ideal for open kitchens, e.g. in hotels. Noise level: <70 dB;

Maximum convenience for the user

The side exit for cut vegetables ensures better ergonomics of work, even on a narrower worktop. Very intuitive electronic control panel.

ULTRA models with brushless technology:

- they are highly efficient because they work at the same power over the entire speed range.

- guarantee uniform, repeatable cutting results and reduce losses on the product thanks to the exclusive Force Control System

- They are distinguished by a better tightness of the housing due to the lack of the need for ventilation, which also reduces noise emissions and improves the comfort of work

- are easy to use thanks to the new, ergonomic control panel

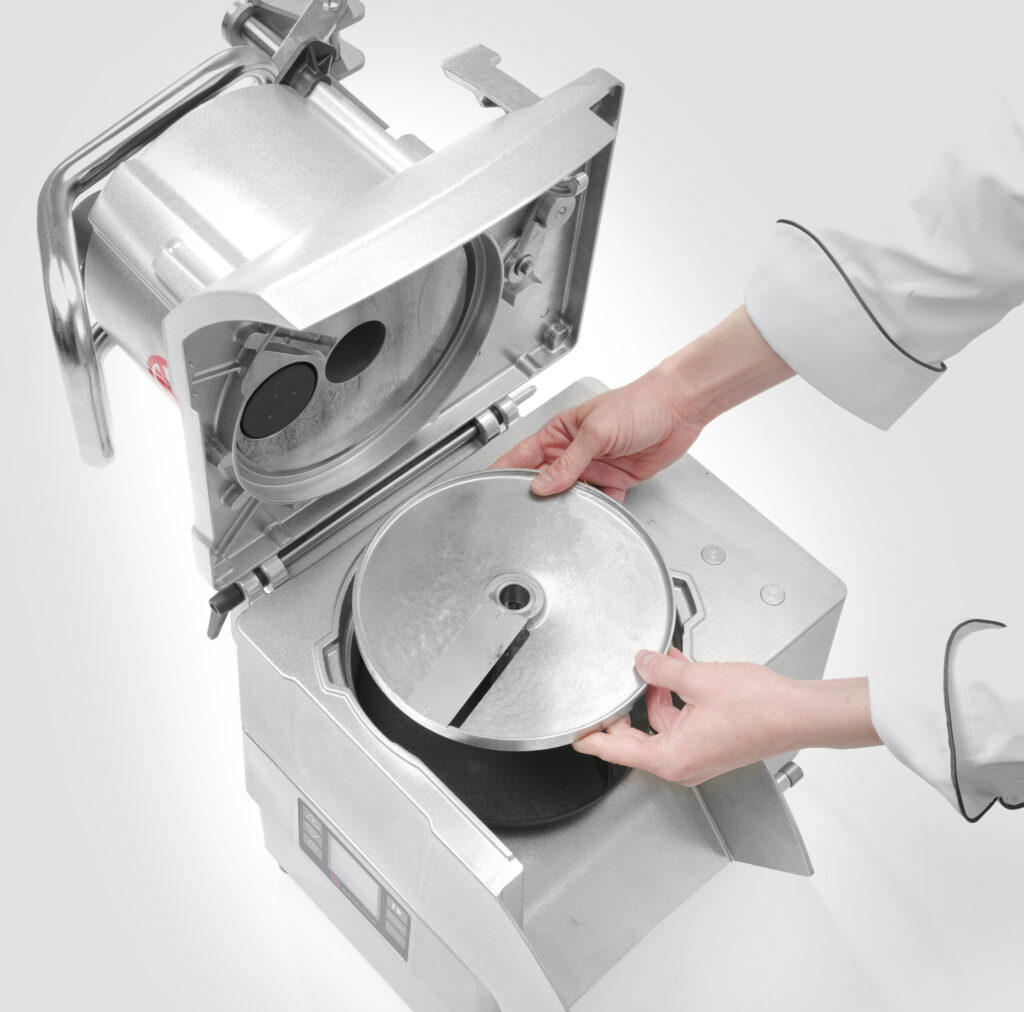

Cutters and cutters-emulsifiers

Adapted to intensive and failure-free operation.

Solid construction made of stainless steel and aluminum ensures high durability and resistance to working conditions

Adapted to intensive and failure-free operation

solid construction made of stainless steel and aluminum ensures high durability and resistance to working conditions

Ergonomics and work control

cover made of highly resistant polycarbonate with a hole with a cap that allows you to add ingredients while the device is running

Working with the most delicate products

thanks to the pulse mode, the knife does not heat up

Security

two safety microswitches in the vessel and lid position – after removing the lid and / or vessel, the engine automatically turns off

ULTRA models are equipped with brushless technology for maximum efficiency and comfort. The engines are powerful and efficient.

- maintenance of torque in each speed range

- an exclusive force control system guarantees uniform, repeatable cutting results and reduced product losses

- better tightness of the housing due to the lack of the need for ventilation prevents the engine from flooding

- lower noise emissions have a positive effect on working conditions

- adjustable speed of rotation in 10 stages in the range from 385 to 3000 rpm

- advanced, very intuitive control panel providing immediate full information

Multifunctional devices

Sammic multifunctional robots combine the advantages of using choppers with variable speed with emulsifiers.

The offered models meet all the user’s expectations and give the opportunity to choose the best solution depending on the needs.

Each of them is equipped with 3 basic elements:

- block with engine (common to all models of multifunctional robots)

- vegetable cutter head (two models to choose from)

- cutter-emulsifier tank (choice of two capacities of 5.5 or 8 liters)

Block with engine

common to all models of multifunctional robots

Vegetable cutter head

two models to choose from

Cutter-emulsifier tank

choice of two capacities of 5.5 or 8 liters

- The engine block is made of high-class aluminum alloy

- User-friendly electronic, waterproof control panel with LED backlight

- A timer that allows you to program the work time in the range from 0 to 10 minutes in increments of 0.5 minutes

- Pulse mode button (only for idle speed)

- Speed, time and error codes display

- Activity counter to optimize work and control operating costs

- Two safety microswitches in the vessel and lid position – when the lid and / or vessel are removed, the engine automatically shuts down

- Easy to use and keep clean

- Designed for grinding vegetables using a wide range of discs and grids available as an OPTION possibility to obtain slices, chips, bars, cubes and fries of various thickness

- Made of cast aluminum, it is distinguished by high durability and adaptation to intensive work

- Equipped with a large tray for vegetables: 136 cm² or as much as 286 cm² (depending on the model)

- Side outlet for the finished product that allows you to set the machine on a small work surface

- 5-step speed regulation in the range from 300 to 1000 rpm

- Profiled evacuation disk increasing the efficiency of the device

- Productivity: 100 – 650 kg / hour (depending on the model)

- The idler design with rotating handle minimizes stress on the elbow and wrist

- Easily removable lever and cover for easy cleaning

- NOTE: blades must be ordered separately – see pages 502-503

- Designed for crushing, chopping, grinding and mixing all kinds of products, such as vegetables and herbs, raw and cooked meats, fish, fruit, nuts, ice cubes and for kneading all kinds of dough

- Especially designed for working with liquids

- 10 speeds available, ranging from 300 to 3000 rpm

- Removable stainless steel tank (5.5 or 8 liters depending on the model) with a polycarbonate lid with an opening for adding ingredients while the device is running

- A serrated knife is included

- A scraper for additional mixing

Hand mixers

The new series of modern Sammic XM hand blenders are devices designed with every detail in mind, designed for professionals for continuous operation.

- professional Y-shaped knife with three hardened steel blades – efficient and reliable.

- variable speed – ensures perfect work results.

- ideal for continuous operation.

- designed to work with containers with a capacity of 10 to 250 liters (depending on the model).

- an additional MA series mixing arm can be purchased.

- compact design: convenient and easy to operate.

- bi-material outer casing to ensure ergonomic grip. Non-slip handle and optimal handle inclination minimize fatigue.

- click-on-arm: removable arm with quick and safe closure.

- splash protection.

- intuitive operation: very easy to use. In addition, the indicator light for connecting the device to the network guarantees the operator’s safety – the indicator light turns on as soon as the mixer is connected to the power source.

Planetary mixers

Planetary mixers designed for intensive use.

- Table model with a bowl with a capacity of 5 liters

- Smooth electronic speed control

- Lever for easy lifting and lowering of the bowl

- Bowl safety cover

- Double safety microswitches that turn off the device when the bowl is lowered or the bowl’s safety cover is not properly installed

- Compact, universal design

- Device with international NSF certificate (compliance with hygiene, cleanliness and food raw materials regulations)

- Standard equipment: 5-liter stainless steel bowl, hook, flat stirrer, wand

- The bowl’s capacity ranges from 10 to 40 liters, depending on the model

- Powerful, highly reliable motor with electronic speed control that allows the mixers to be connected to a single-phase power source

- Electronic speed control – 10 speed levels

- Electronic timer 0-30 minutes and option of continuous operation

- Bowl safety cover

- Double safety microswitches

- Lever for easy lifting and lowering of the bowl

- Display of operating parameters

- Reinforced waterproof system of the motor housing and control panel

- Stainless steel legs

- Easy to maintain and service

- Standard equipment: 5-liter stainless steel bowl, hook, flat stirrer, wand

Turbo Mixer – TRX-22 SERIES

with high performance for the most demanding!

- Turbo mixer designed for mixing and grinding food in vessels with a capacity of up to 800 liters, i.e. in high-capacity kitchens and even in the food industry

- Perfect for mixing food directly in the brew kettle

- The 600 mm arm blends equally effectively in any type of vessel, round or rectangular. Made entirely of 18/10 stainless steel

- Ease of use: can move in different directions, height adjustable, trolley mount with 4 non-slip rubber wheels, including 2 with brakes

- Perfect balance of the chopping arm prevents the machine from tipping over or tilting backwards, even if the arm or the base wheels are not blocked

- The safety lever allows you to lock the arm with one hand

- Easily accessible, watertight, tilt control panel

- Speed control on two levels: 750 and 1500 rpm

- Control panel with built-in timer: the device can be left running for up to 60 minutes without the need to control it

- Possibility of hanging electric cables on the trolley frame, which makes work safe and comfortable

- Turbine, guard, shield and cap are easily removable. They can be washed in the dishwasher

- Safety microswitch controlling the position of the device: it does not allow the turbine to work when the arm is too high or too low

- For use with 3 optional and easily interchangeable mixing sieves

High performance meat grinder

- The perfect solution when you want to decide for yourself about the individual items of equipment for your meat grinder.

- You order the drive and a separate throat with the cutting unit, which is available in two variants: “ENTERPRISE” and “UNGER”.

Both units are made of stainless steel and as standard they are equipped with a screw and a strainer with holes ø6 mm. They differ, however, with a knife that may have cutting edges on one or both sides.

Potato processing equipment

- Compact peeler for potatoes, beetroots, carrots and other tuberous vegetables made of stainless steel

- Perfect for small gastronomy – specially designed with limited space in mind

- capacity 5 kg per cycle

- Easy to install, it can also be positioned on a stainless steel base with an optional filter chamber

- The lower part of the chamber in the form of a rotating plate lined with abrasive material

- Water supply system equipped against the backflow of water into the network.

- Professional equipment for peeling potatoes, beets, carrots and other tuberous vegetables made of stainless steel

- Capacity 10 to 30 kg per cycle

- The lower part of the chamber in the form of a rotating plate lined with abrasive material

- 2 or 3 side abrasive elements (depending on the model)

- The flip-up transparent polycarbonate lid allows you to control the process

- Lid and door safety switch

- Tightness factor: IP65 – high resistance to moisture and water splashing

- Equipped with a timer and the possibility of continuous operation.

- Automatic dragging of waste to the sewage system.

- Water supply system with air return gap.

- Auxiliary contact for external electric valve.

- Energy efficiency through engine optimization.

- Fast, elegant, quiet and user-friendly

- A safe, smooth-running commercial centrifuge for salads and other vegetables and fruits

- Designed for efficient drying up to 12 kg. lettuces per cycle at a maximum speed of 900 rpm. (2 speeds)

- Portable, equipped with lockable wheels. Cycle memory.

Comfort and ergonomics at work

- Specially designed pulp container lids prevent clogging

- The automatic pulp ejection system extends the working time of the device

- Pulp container with a capacity of 3¼ l

- The large feeding opening of Ø75 mm shortens the time of juice preparation

- The turbo switch increases the revolutions in time, balances possible vibrations and enables cleaning of the basket

Vacuum packing machines

- from 1 to even 4 sealing bars enables packing several bags at the same time

- a double seal line on each strip guarantees tightness and durability of the packaging

- single-piece pressed chamber for easy cleaning

- wireless sealing bar facilitates assembly and disassembly, easy to clean

- the percentage of vacuum sensor allows you to set the vacuum at the level of up to 99%

- maximum performance

- work comfort

- easy to clean

closing bags without air suction and marinating products

All models are equipped with a Busch pump that guarantees efficiency and savings

- the oil vacuum pump has the function of oil regeneration Dry Oil – the oil drying program extends the service life and the operating hours counter helps to determine the time of oil change

- less frequent oil changes thanks to the regeneration function means saving money and respecting the natural environment

- effectiveness

- savings

- care for the environment

- wireless connection to a dedicated application for program management

- the ability to store up to 25 different vacuum programs with the possibility of locking to avoid accidental changes

- wireless connection

- easy management of vacuum programs

3.9” color LCD screen. The illuminated touch keyboard made of scratch-resistant plastic is protected against splashing liquids

- easy-to-read screen

- backlit touch keyboard

- The “PLUS” welding system for welding bags made of thicker films and metallised bags – useful e.g. in food processing

- External vacuum set Vac-Norm for packaging in special containers with automatic suction controlled by a sensor

- The protective gas injection system enables vacuum packaging of food in an oxygen and water vapor-free atmosphere which allows for better protection of the product against the growth of bacteria reduces the risk of damage to delicate products and improves their appearance and extends their shelf life

- Label printing system with the option of connecting a printer with self-adhesive, frost-resistant labels. The label texts are entered via an application developed for mobile devices connected to the packaging machine via Bluetooth

The offer also includes a two-chamber packaging machine

- The set includes 4 filling plates made of polycarbonate

- Thick cover made of durable stainless steel

- High capacity model with hinged lid, double chamber and 4 x 662 mm. sealing strips.

- Busch vacuum pump.

- Vacuum controlled by sensor.

- from 1 to 2 sealing bars enables packing several bags at the same time

- a double seal line on each strip guarantees tightness and durability of the packaging

- single-piece pressed chamber for easy cleaning

- wireless sealing bar facilitates assembly and disassembly, easy to clean

- the percentage of vacuum sensor allows you to set the vacuum at the level of up to 99%

- simultaneous packing of several bags

- guarantee of tightness and durability of the packaging

- easy to clean

closing bags without air suction and marinating products

- sensor-controlled step-by-step suction program for delicate textured products

- evaporation point detection system – automatically stops the suction process, blocks the suction of liquids, ensuring the maximum possible vacuum. It enables packaging of liquids and products with high water content e.g. fruit

All models are equipped with a Busch pump for efficiency and savings

- the oil vacuum pump has the function of oil regeneration Dry Oil – the oil drying program extends the service life and the operating hours counter helps to determine the time of oil change

- less frequent oil changes thanks to the regeneration function means saving money and respecting the natural environment

- effectiveness

- savings

- care for the environment

backlit keyboard made of scratch-resistant plastic protected against liquids

- intimate

- easy-to-read control panel

- backlit keyboard

- External vacuum set Vac-Norm for packaging in special containers with automatic suction controlled by a sensor

- The bluetooth system allowing you to wirelessly connect to a dedicated application

Cutlery polishers

Machines for drying and polishing cutlery. Sammic cutlery polishers dry, polish and eliminate washing stains on cutlery.

- Perfect for drying and polishing cutlery

- Fully automated process

- Sterilization of cutlery with a bactericidal UVC lamp

- The round shape of the drum prevents the cutlery from jamming

- Engine brake (on selected models)

- Air cooling of the engine with a fan

- Stainless steel housing

- Free-standing models with 2 wheels and 2 feet.

- Additional 2 wheels as an option

- Polishing agent included

Completely automatic. Savings, time savings, hygiene